RKB Guidelines for Mounting Medium to Large TQO Bearings Poster0 pages

MOUNTING GUIDELINES FOR RKB TQO/TQOS BEARINGS

IN ROLLING MILL APPLICATIONS (BORE DIAMETER OVER ABOUT 450 MM)

DD spacer width

E

D

BB spacer width

D

B

E

C

B

A

C

A

CC spacer width

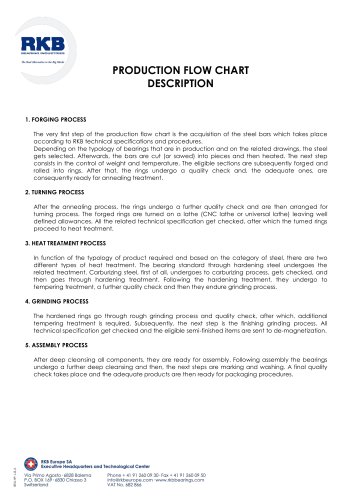

PRELIMINARY OPERATIONS

1

2

a

b

c

d

3

4

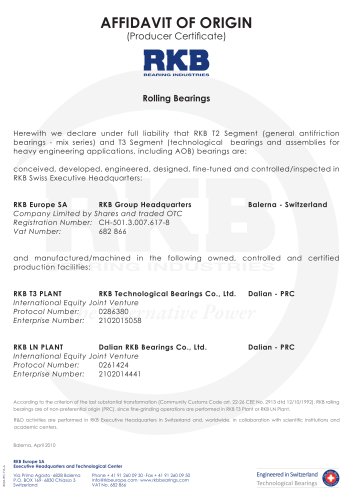

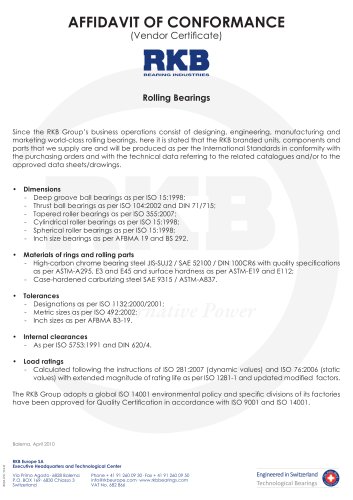

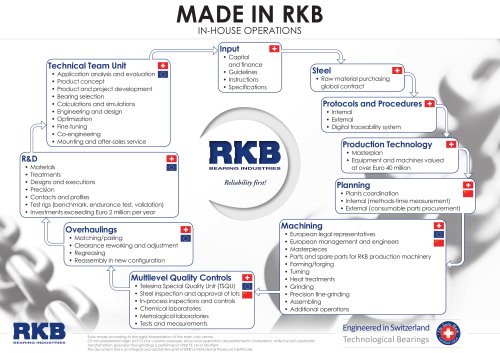

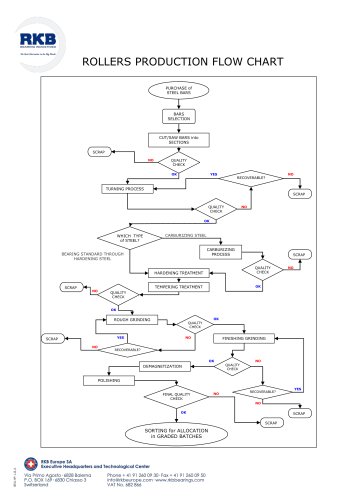

•t RKB four-row taper roller bearings in TQO configuration are generally composed of two double cone assemblies (AC and CE), one central double cup

(BD), two single cups (AB and DE) and three factory adjusted spacers: two cup spacers (BB and DD) and one cone spacer (CC).

•t RKB TQO bearings may be manufactured in different configurations: with cylindrical/tapered bore, with/without seals, with/without helical grooves on

cone bores and with/without spacers.

•t The spacers are face ground after accurate measurements of the gaps between adjacent cups and cones to obtain the required initial axial clearance

(B.E.P. - Bench End Play).

•t Due to the special operating conditions (contaminated environments, high temperatures, presence of vibrations and shocks), adequate lubrication is

required and the use of an effective sealing system is highly recommended.

•t The TQOS version has seals fitted on both sides of the bearing, one cone seal set and O-type seal rings on the outer surfaces of the single cups.

•t The mounting of the bearing onto the roll neck has to be in accordance with the mounting instructions supplied with the rolling mill machinery design.

•t For bore diameters over about 450 mm, the mounting has to be performed with the bearing assembled as shown in the below procedure.

•t Prior to mounting, measure the chock bore diameter in four equally spaced planes normal to the bore axis of symmetry (a, b, c, d) and in each plane

in four directions offset at 45° (1, 2, 3, 4). These measurements have to be properly recorded.

•t Carry out the same procedure for the shaft.

•t Bore and shaft shape deviations are highly recommended to be measured as well.

•t Properly lubricate bearing components according to the lubricant suggested in the rolling mill machinery design.

•t For easy mounting, be sure that the chock and the shaft are clean and lubricated; this will reduce the wear and corrosion of the assembly elements

during operation.

•t Fasten the roll-side cover onto the chock.

•t Place the chock on level supports with

bore axis in vertical position.

•t Place the single cup DE into the chock and

check the seating of the cup against the

cover shoulder with a feeler gauge.

STEP I

•t Add the cup spacer BB, which is provided

with lubrication holes.

STEP VI

•t Add the double cone AC with side C facing

down.

•t Handle the cone with care: do not place it

on (or hang it from) the cage, but only on

(or hang it from) the inner ring.

•t Rotate the cone to seat the rollers in proper

position.

•t Add the cup spacer DD, which is provided

with lubrication holes.

•t Take care not to cause nicks on the chock

bore surface or burrs on the spacer.

STEP II

STEP VII

•t Insert the double cone CE with side E facing

down.

•t Handle the cone with care: do not place it

on (or hang it from) the cage, but only on

(or hang it from) the inner ring.

•t Rotate the cone to seat the rollers in proper

position.

STEP III

•t Add the single cup AB.

WARNING!

All the cups need to be placed so that the

marked zones are aligned.

STEP VIII

•t Add the cone spacer CC.

The cone spacer has a special design with

equally spaced lubrication slots, whose

purpose is to let lubricant go through the

bearing to the roll neck.

G

STEP IV

STEP IX

•t Insert the double cup BD.

CBA

STEP V

•t Mount the chock cover without gasket.

•t Tighten evenly four equally spaced cap

screws, until the cover is uniformly seated

against the side face of the chock, and

cups and cup spacers abut each other.

•t Measure the width of the gap (G) between

the cover and the chock and establish the

gasket or metallic shim set final thickness.

•t Remove the cover, insert the gasket or

metallic shim set of required thickness and

mount the cover.

STEP X

•t Push the labyrinth ring (heated in an oil

bath) onto the roll neck.

•t Align the chock with the shaft.

•t Mount the seal neighboring the shaft

shoulder and push the chock onto the roll

neck with side E forward until side E of the

double cone abuts the labyrinth ring.

•t Mount the remaining seal, spacer (A), nut

(B) and split clamping ring (C) into position.

•t Tighten the nut until it abuts the clamping

ring and the spacer abuts the bearing

cone.

•t Loosen the nut in order to leave an

appropriate axial clearance, which

enables free cone rotation and prevents

wear to the cone faces.

DISMOUNTING

If the bearing has to be dismounted for inspection and maintenance, dismounting will be performed in the reverse order of mounting. It is important to use appropriate tools and follow the above instructions and recommendations to avoid bearing damage.

W W W. R K B B E A R I N G S . C O M

ENGINEERED IN SWITZERLAND

TECHNOLOGICAL BEARINGS

عضویت

عضویت  ورود اعضا

ورود اعضا راهنمای خرید

راهنمای خرید