LOADING

DESIGN OF PLASTIC GEARS0 pages

نسخه متنی

"

"

| SECTION 18 DESIGN OF PLASTIC GEARS 18.1 General Considerations Of Plastic Gearing Plastic gears are continuing to displace metal gears in a widening arena of applications. Their unique characteristics are also being enhanced with new developments, both in materials and processing. In this regard, plastics contrast somewhat dramatically with metals, in that the latter materials and processes are essentially fully developed and, therefore, are in a relatively static state of development. Plastic gears can be produced by hobbing or shaping, similarly to metal gears or alternatively by molding. The molding process lends itself to considerably more economical means of production; therefore, a more in-depth treatment of this process will be presented in this section. Among the characteristics responsible for the large increase in plastic gear usage, the following are probably the most significant: 1. Cost effectiveness of the injection-molding process. 2. Elimination of machining operations; capability of fabrication with inserts and integral designs. 3. Low density: lightweight, low inertia. 4. Uniformity of parts. 5. Capability to absorb shock and vibration as a result of elastic compliance. 6. Ability to operate with minimum or no lubrication, due to inherent lubricity. 7. Relatively low coefficient of friction. 8. Corrosion-resistance; elimination of plating, or protective coatings. 9. Quietness of operation. 10. Tolerances often less critical than for metal gears, due in part to their greater resilience. 11. Consistency with trend to greater use of plastic housings and other components. 12. One step production; no preliminary or secondary operations. At the same time, the design engineer should be familiar with the limitations of plastic gears relative to metal gears. The most significant of these are the following: | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1. Less load-carrying capacity, due to lower maximum allowable stress; the greater compliance of plastic gears may also produce stress concentrations. 2. Plastic gears cannot generally be molded to the same accuracy as high-precision machined metal gears. 3. Plastic gears are subject to greater dimensional instabilities, due to their larger coefficient of thermal expansion and moisture absorption. 4. Reduced ability to operate at elevated temperatures; as an approximate figure, operation is limited to less than 120°C. Also, limited cold temperature operations. 5. Initial high mold cost in developing correct tooth form and dimensions. 6. Can be negatively affected by certain chemicals and even some lubricants. 7. Improper molding tools and process can produce residual internal stresses at the tooth roots, resulting in over stressing and/or distortion with aging. 8. Costs of plastics track petrochemical pricing, and thus are more volatile and subject to increases in comparison to metals. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

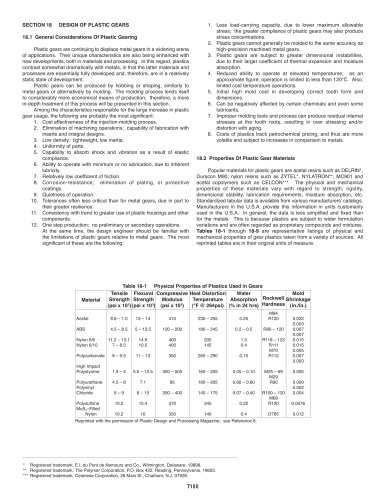

| 18.2 Properties Of Plastic Gear Materials Popular materials for plastic gears are acetal resins such as DELRIN*, Duracon M90; nylon resins such as ZYTEL*, NYLATRON**, MC901 and acetal copolymers such as CELCON***. The physical and mechanical properties of these materials vary with regard to strength, rigidity, dimensional stability, lubrication requirements, moisture absorption, etc. Standardized tabular data is available from various manufacturers' catalogs. Manufacturers in the U.S.A. provide this information in units customarily used in the U.S.A. In general, the data is less simplified and fixed than for the metals. This is because plastics are subject to wider formulation variations and are often regarded as proprietary compounds and mixtures. Tables 18-1 through 18-9 are representative listings of physical and mechanical properties of gear plastics taken from a variety of sources. All reprinted tables are in their original units of measure. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

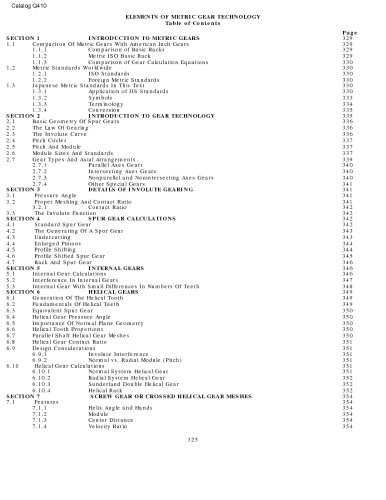

| Table 18-1 Physical Properties of Plastics Used in Gears | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Reprinted with the permission of Plastic Design and Processing Magazine; see Reference 8. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| * Registered trademark, E.I. du Pont de Nemours and Co., Wilmington, Delaware, 19898. ** Registered trademark, The Polymer Corporation, P.O. Box 422, Reading, Pennsylvania, 19603. *** Registered trademark, Celanese Corporation, 26 Main St., Chatham, N.J. 07928. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

عضویت

عضویت  ورود اعضا

ورود اعضا راهنمای خرید

راهنمای خرید